February 4, 2020

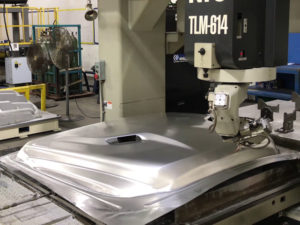

We have stamping presses to meet virtually any of your prototype sheet metal needs. With 36 presses ranging from 150 to over 2,500 tons and bed sizes up to 240” x 96” we have the ability to stamp the parts your project requires. Our in-house foundry allows us to produce tooling for tight time schedules and incorporate changes very quickly. We utilize traditional production processes in our prototype projects, allowing for greater repeatability and accuracy. Contact us to see how our 60 years of prototype experience can benefit your next project.